Jumbo Bags

At Positra Packaging Pvt. Ltd., we specialize in manufacturing and supplying high-quality Jumbo Bags, also known as Flexible Intermediate Bulk Containers (FIBCs). These versatile and durable bulk packaging solutions are designed to meet the diverse needs of various industries, ensuring the safe and efficient handling of materials.

Understanding Jumbo Bags

Jumbo Bags are large, flexible containers made from woven polypropylene fabric, engineered to store and transport bulk quantities of dry, flowable materials. Their design facilitates easy handling, storage, and transportation, making them indispensable in sectors such as agriculture, chemicals, pharmaceuticals, and construction.

Our Range of Jumbo Bags

We offer a comprehensive selection of Jumbo Bags, each tailored to specific applications and requirements:

4 Panel Bags

- Construction: Comprises four individual panels sewn together, forming a robust square structure.

- Fabric Weight: Ranging from 100 GSM to 300 GSM.

- Features: UV-stabilized polypropylene fabric, available in coated or uncoated variants, with dust-proof seams.

- Safe Working Load (SWL): Options include 1000 kg, 1250 kg, 1500 kg, 2000 kg, and 2500 kg.

- Safety Factor: 5:1 or 6:1, ensuring reliability under specified loads.

- Customization: Sizes and specifications can be tailored to meet customer requirements.

Circular With Cross Corner Loops Bags

- Construction: Crafted from tubular fabric, eliminating side seams, and featuring cross-corner loops stitched onto the body.

- Fabric Weight: From 140 GSM to 300 GSM, including reinforcement.

- Features: UV-stabilized polypropylene fabric, available in coated or uncoated forms, with dust-proof seams.

- SWL: 1000 kg, 1250 kg, 1500 kg, and 2000 kg.

- Safety Factor: 5:1 or 6:1.

- Customization: Dimensions and specifications are customizable as per client needs.

U Panel Bags

- Construction: Consists of a continuous piece of fabric forming the bottom and two opposite sides, with two additional side panels.

- Fabric Weight: Between 100 GSM and 300 GSM.

- Features: UV-stabilized polypropylene fabric, coated or uncoated, with dust-proof seams.

- SWL: 1000 kg to 2000 kg.

- Safety Factor: 5:1 or 6:1.

- Customization: Tailored sizes and specifications to suit specific applications.

One / Two Loop Lifting Bags

- Construction: Made from tubular fabric with one or two lifting loops integrated from the body fabric.

- Fabric Weight: 90 GSM to 300 GSM.

- Features: UV-stabilized polypropylene fabric, available in coated or uncoated options, with optional liners (loose inserted, gusseted, suspended, or fully glued).

- SWL: 500 kg, 600 kg, 1000 kg, 1250 kg, and 1500 kg.

- Safety Factor: 5:1 or 6:1.

- Customization: Sizes and specifications can be customized as per requirements.

UN Certified FIBC’s Bags

- Purpose: Designed for the transportation of hazardous or dangerous materials, adhering to stringent safety standards.

- Types Offered:

- 13 H1: Uncoated PP FIBC without liner.

- 13 H2: Coated PP FIBC without liner.

- 13 H2Y: Single-layer UN FIBC with parameters similar to double-layer FIBC.

- 13 H3: Uncoated PP FIBC with liner.

- 13 H4: Coated PP FIBC with liner.

- SWL: 500 kg to 1500 kg.

- Safety Factor: 6:1, ensuring enhanced safety for hazardous materials.

- Customization: Dimensions and specifications are customizable to meet regulatory and client requirements.

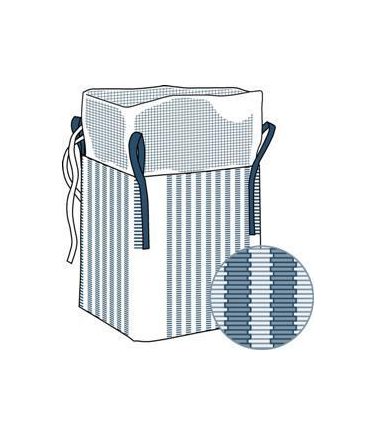

Ventilated Big Bags

- Construction: Manufactured from Sulzer loom flat fabric with ventilation stripes.

- Ventilation Options: 13 vents, 16 vents, or 23 vents, based on customer needs.

- Features: Locked or unlocked ventilation stripes, UV-stabilized fabric.

- SWL: 1000 kg to 2000 kg.

- Safety Factor: 5:1 or 6:1.

- Customization: Sizes and specifications can be tailored as per requirements.

Q-Bags (Baffle Bags)

- Construction: Four-panel design with internal baffles stitched diagonally to maintain a square shape when filled.

- Fabric Weight: 100 GSM to 300 GSM.

- Features: UV-stabilized polypropylene fabric, coated or uncoated, with dust-proof seams.

- SWL: 1000 kg to 2000 kg.

- Safety Factor: 5:1 or